“The Anvil” Inside Your Electrostatic Precipitator: Small Part, Big Performance Boost

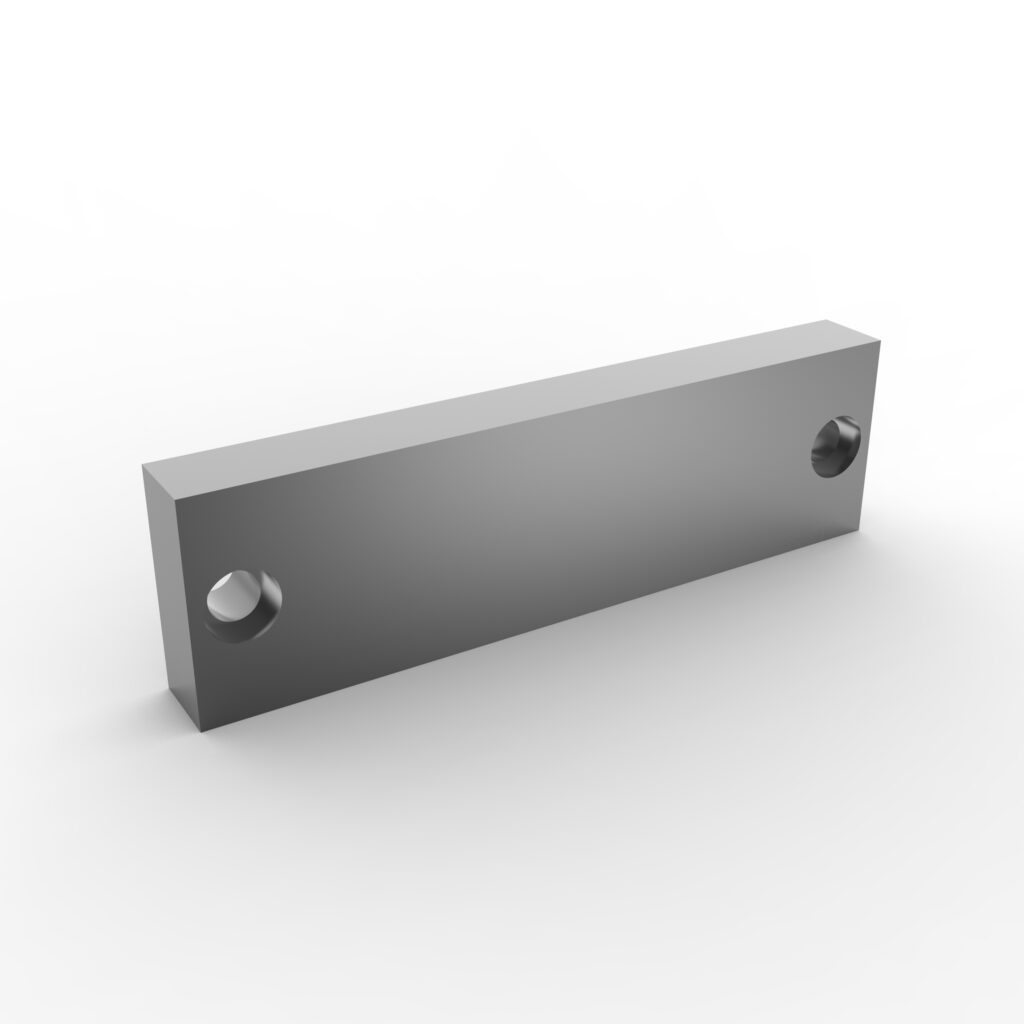

Electrostatic precipitators (ESPs) owe their dust-knocking power to dozens of components working in concert, but few are as deceptively important as the anvil.

This rugged metal block is the silent partner in a hammer-and-anvil rapping system that keeps plates and electrodes clean, efficient and within emission limits. Below is a deep dive into what the anvil does, how it is built, and why upgrading or maintaining it properly can translate into measurable gains in collection efficiency and plant uptime.

1 | What exactly is an anvil in an ESP?

In most dry ESPs, particulate matter builds up on collecting plates and must be dislodged before it insulates the plate surface. Mechanical rapping systems achieve this by lifting a hammer that then free-falls and strikes an anvil welded or bolted to a rapping beam at the plate edge. The impact creates a shock wave that travels through the beam and into the plates, shaking dust loose so it falls into the hopper.

2 | Core design features of a modern anvil

| Design aspect | Why it matters |

|---|---|

| Heat-treated alloy steel or cast iron body | Must withstand millions of high-energy blows without cracking or mushrooming. |

| Integral shank & head | A unitized forging reduces stress risers between shank and impact face. |

| Precision head geometry | A slightly crowned face centers the hammer strike and prevents glancing blows. |

| Positive retention system | Crimped-tube, wedge collar or through-bolt prevents loosening under vibration. Google Patents |

Patented shank-in-tube designs, such as the crimp-retained anvil arrangement shown in U.S. Patent 5,639,359, further simplify retrofits by slipping into existing discharge-electrode tubes and being locked in place with a single crimp.

3 | How anvil quality impacts ESP performance

Dust-removal efficiency – A correctly sized anvil delivers the necessary peak acceleration to shed the agglomerated dust layer in one or two knocks, minimizing re-entrainment. Poorly machined faces dissipate energy, leaving “mud-flats” of dust that lower collection efficiency. OSTI

Rapper motor power draw – Because the hammer need not be lifted as high when the anvil’s rebound is optimal, drive-motor current can drop by 5–10 %, saving auxiliary power.

Plate and frame fatigue – A balanced hammer-anvil pair concentrates shock on the plate edge or anvil beam rather than on hanger rods, reducing micro-cracks and extending plate life.

Maintenance intervals – Heat-treated anvils can exceed 50 million cycles before resurfacing is needed, versus 10–15 million cycles for softer castings.

4 | Specifying or retrofitting an anvil

| Step | Practical tip |

|---|---|

| Performance audit | Record rapper motor current, dust re-entrainment levels and hopper dust load to quantify current rapping efficiency. |

| Match hammer mass & drop height | Use manufacturer charts or run a modal analysis to ensure impact force (F = m · g · h) matches ash characteristics. |

| Select material | Fly-ash or sinter service often uses 4140 or 4340 quenched-and-tempered steel; acidic gas streams may require high-chromium cast alloy. |

| Installation | Verify anvil-to-beam face is flush; shim if necessary. Torque bolts or apply prescribed crimp depth to eliminate “ring-off” gaps. |

| Commissioning | Start at conservative rapping frequency; incrementally raise until dust fall-off equals design. |

5 | Maintenance best practices

Visual inspections at outage: look for head mushrooming > 2 mm or shank wear > 5 %.

Magnetic particle testing every two outages if the plant runs above 450 °C flue-gas temperature.

Surface grinding & re-hardening: re-establish crown radius and perform induction-hardening to ≥ HRC 55 when cumulative wear reaches 25 % of head height.

Bolt or crimp checks whenever hammer timing or plate alignment work is performed.

6 | Case snapshot – 1 % opacity drop with anvil upgrade

A 200 MW Indian coal boiler retrofitted its 1980-era cast-iron anvils with forged alloy units of identical footprint. Post-upgrade data showed:

| Metric | Before | After |

|---|---|---|

| Plate rapping intensity | 1.8 g | 2.3 g |

| Average stack opacity | 7 % | 6 % |

| Rapper motor current | 28 A | 25 A |

Annualized cost savings (aux load + avoided derates) paid back the retrofit in under nine months.

7 | Takeaway

Despite its modest size, the anvil is a linchpin in the ESP’s self-cleaning system. Attention to metallurgy, geometry and proper pairing with the hammer can deliver real-world gains in particulate removal, energy consumption and component longevity. During your next outage walk-down, give the anvil the same scrutiny you give plates, electrodes and transformers – your stack readings (and local regulators) will thank you.

Need help selecting the right anvil for your precipitator model or ash chemistry? Let’s talk – we can run an impact-energy simulation and suggest a spec that slots straight into your existing rapper beam.